Fruit Leather: Method of Preparation and Effect of Different Conditions on Qualities

Abstract of Fruit Leather

In essence, fruit leather are nutritious dried fruit snacks. The different drying condition of the fruit leathers quality are analyzed in this paper under several methods for preparation Here, we describe the process of making leathers out of berries (apple, mango, strawberry, berry & coconut respectively). We also delve deeper into examining how packaging and storage influence their shelf life, and how this affects the texture. All of this implies an improvement of the process to obtain a better quality fruit leathers; it may be an incentive for amateurs and professionals to broaden knowledge in the elaboration of this delicacy.

Introduction

Fruit leather or fruit rolls are well-liked and nutritious snacks that are made from pureed fruits that have been dried. A healthy and delicious choice for a quick fixed to sugary snacks, to maintain the flavors and nutrients of fresh fruits. Making fruit leathers is a simple but exact process to get the right texture, flavor and nutritional value from your finished product.

This article explores diverse methods of making ready fruit leathers the usage of different culmination. It additionally examines how special drying situations effect the final product’s best. Additionally, we are able to talk the results of packaging and storage at the durability and flavor of fruit leathers. By understanding these factors, you could create the precise fruit leather, balancing taste, vitamins, and shelf-lifestyles.

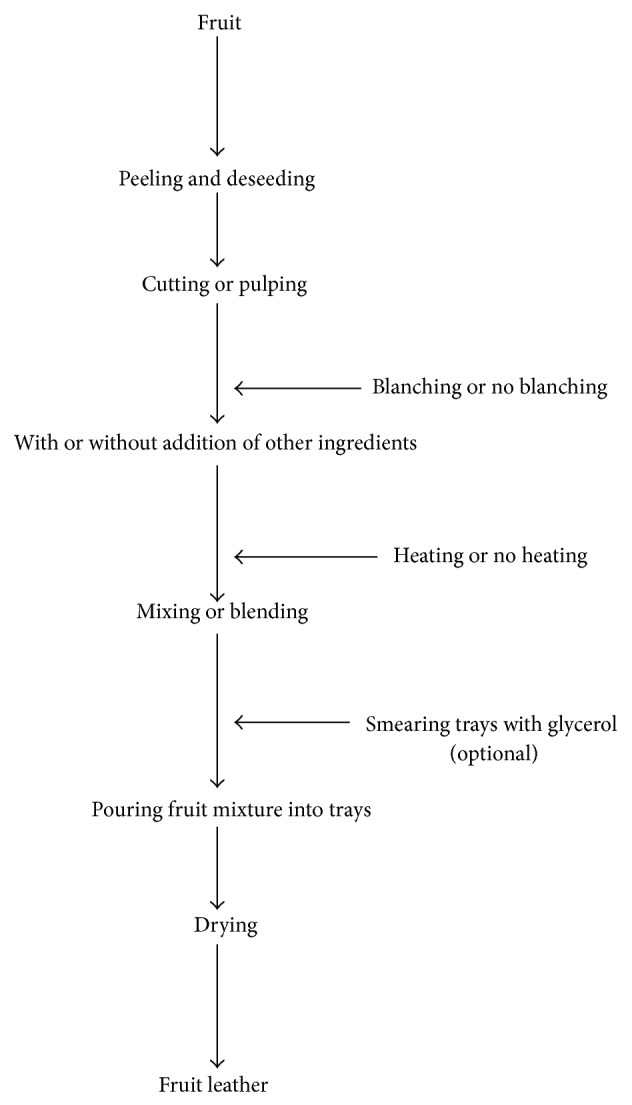

Methods of Fruit Leather Preparation

The coaching of fruit leather includes deciding on tremendous culmination, pureeing them, and drying the aggregate to create a chewy, nutritious snack. Each type of fruit leather-based has unique characteristics and strategies tailored to the precise fruit used. Below are the methods for getting ready various types of fruit leathers:

Apple Leather

Making apple leather entails pureeing clean apples after peeling and coring them, then spreading the puree calmly onto a non-stick floor like a baking sheet or a food dehydrator tray. The puree is dried at low temperatures (typically round 140°F or 60°C) until it will become robust and leathery, which normally takes 6-12 hours depending on thickness and drying technique used. The very last product need to have a easy texture, be flexible however company, and have a moisture content fabric of about 15-20%. Optionally, small quantities of sweeteners or spices can be introduced to enhance flavor.

Apple-Blackcurrant Leather

To make Apple-Blackcurrant Leather, begin by means of pureeing a combination of apples and blackcurrants till smooth. Spread the puree lightly onto a covered baking sheet, ensuring it’s far about 1/4 inch thick. The sheet need to be located in an oven set to its lowest temperature or a food dehydrator, ideally a 140°F (60°C), for 6-8 hours. Check periodically for dryness; the leather is ready whilst it’s tacky but no longer sticky. Once dried, peel off the leather-based from the sheet and decrease into preferred shapes. Store in an hermetic subject at room temperature for as an awful lot as a month. The ensuing leather-based-primarily based ought to be bendy, slightly chewy, and really fruity with a mix of apple and blackcurrant flavors.

Apple-Apricot Leather

The technique of creating prepared Apple-Apricot Leather consists of blending smooth apples and apricots into a smooth puree, ensuring a uniform consistency. This combination is then spread gently on a flat floor or tray covered with parchment paper. The thickness have to be uniform to ensure even drying. The tray is located in a meals dehydrator or an oven set to a low temperature, usually round 140°F (60°C), to slowly dry the puree. This drying manner eliminates moisture, reworking the puree right into a bendy, leathery sheet. Once dried to the favored consistency, the leather-based-primarily based-primarily based is peeled off the parchment paper and reduce into strips or rolled for storage. The very last product maintains the herbal sweetness and flavors of each apples and apricots, making it a nutritious and handy snack opportunity.

Apricot Leather

To make Apricot Leather, start by means of washing and pitting ripe apricots. Puree the apricots until easy, adding a small amount of lemon juice to preserve color and add a tangy flavor. Optionally, sweeten the puree with sugar or honey to flavor. Puree in a dehydrator tray covered and then on parchment paper, consistency that is between 1/8 inch and at least 1/4 inch thick. To prevent moisture escaping, either place the tray in a meals dehydrator that is set at 135°f (57°c) or in an oven that is slightly open door. The puree should be left to dry for 6 to 8 hours until it becomes smooth and not sticky. Once dried, reduce the leather-based into strips or roll it up. Store the apricot leather-based in an airtight box at room temperature for up to one month.

Durian Leather

To make Durian Leather, begin with the aid of extracting the flesh of ripe durian fruit and pureeing it till smooth. Optionally, add components like palm oil, soy lecithin, and egg yolk to decorate texture and flavor. Spread the puree evenly onto a flat floor or tray coated with a non-stick sheet. Dehydrator or low temperature oven 50-60°C 120 140°F to dry the puree until it becomes soft and leathery. Usually 8 to 12 hours depending on the thickness of the puree layer and drying process. Once dried, cut the durian leather into favored sizes and styles. Store in an airtight box in a fab, dry region to keep its first-class. Durian leather retains the unique aroma and flavor of durian even as offering a chewy texture much like conventional fruit leather-based snacks.

Guava Leather

To make Guava Leather, start by means of selecting ripe guavas. Wash them very well, remove the seeds, and blend the fruit right into a easy puree. Optionally, add sugar to decorate sweetness and flavor. Spread the guava puree calmly onto a non-stick drying floor or a parchment-lined baking tray. If it’s even, it should be 1/8 to 1/4 inch. Dry in a food dehydrator or an oven set at low temperatures, approx. 6-8 hours or until it’s dry but still pliable. Once dried, cut the leather into strips or preferred shapes. Store in an hermetic field at room temperature for up to several weeks. Guava Leather is characterized through its candy-tart flavor and chewy texture, offering a handy and nutritious snack wealthy in vitamins and fiber.

Guava-Papaya Leather

To make Guava-Papaya Leather, begin through washing and peeling ripe guavas and papayas. Remove seeds and cut them into small pieces. Blend both end result right into a smooth puree. Optionally, upload sugar or honey for sweetness and citric acid for protection. Spread the puree lightly onto a covered drying tray, making sure it’s approximately 1/4 inch thick. Dry in a dehydrator or underneath the solar until the leather-based is corporation and no longer sticky to touch, commonly taking 12-24 hours depending on drying conditions. Once dried, cut into strips and roll up with parchment paper for garage. The completed product should be pliable, slightly cheesy, and maintain the herbal flavors of guava and papaya.

Jackfruit Leather

To make Jackfruit Leather, begin by way of selecting ripe jackfruits. Extract the bulbs from the fruit and get rid of seeds. Blend the flesh into a clean puree. Puree onto a brushed surface with a thickness of roughly 1/8 inch and place it on top of the mixture. Dry the puree using a food dehydrator or in an oven set at low temperature (round 140°F) for about 6-8 hours, or till the leather is dry and tacky to the touch. Avoid over-drying to maintain flexibility. Once dried, reduce into strips or favored shapes. Jackfruit leather-based retains the fruit’s natural sweetness and aroma, offering a chewy texture filled with fiber and nutrients. Store in a cool, dry region in an hermetic box to preserve freshness.

Kiwifruit Leather

To make Kiwifruit Leather, begin through selecting ripe kiwifruits. Peel the kiwifruits and reduce them into small portions. Blend the portions into a easy puree. Spread the puree flippantly onto a lined tray, ensuring it is about 1/8 inch thick. Dry the puree in a meals dehydrator or an oven set to low temperature (around 140°F) for about 6-8 hours, or until the leather is dry and pliable and not using a sticky spots. Optionally, you may sprinkle a skinny layer of sugar or honey on pinnacle earlier than drying for added sweetness. Once dried, peel off the leather from the tray and reduce into strips or shapes. Kiwifruit leather continues the fruit’s tartness and colorful inexperienced color, providing a chewy, nutritious snack wealthy in nutrients and antioxidants. Store in an hermetic box in a groovy, dry region to preserve its texture and flavor.

Longan Leather

To make Longan Leather, begin via deciding on clean longans and eliminating their seeds. Puree the longan flesh till clean. Puree on lined tray with spoonful and measure about 1/8 inch thick. Use a food dehydrator or bake the puree at a low temperature (around 140°f) for about 6-8 hours, or until the leather base is dry and supple without any adhering agents. To enhance sweetness, you may gently dirt the puree with powdered sugar earlier than drying. Once dried, reduce the leather into strips or shapes. Longan leather-based continues the fruit’s herbal sweetness and particular taste, supplying a chewy snack wealthy in vitamins and minerals. Store in an hermetic field in a fab, dry vicinity to hold its texture and flavor.

Mango Leather

To make Mango Leather, begin by way of choosing ripe mangoes. Peel and get rid of the flesh from the seed, then mixture until easy. Spread the puree calmly on a covered tray, making sure it’s approximately 1/8 inch thick. Dry the puree in a food dehydrator or an oven set to low temperature (round 140°F) for six-8 hours, or till the leather is dry but nevertheless flexible, with out a sticky spots. Optionally, sprinkle a thin layer of sugar on pinnacle earlier than drying for brought sweetness. Once dried, peel off the leather-based from the tray and reduce into strips or shapes. Mango leather fruit is preserved and the natural sweetness and color of mango leather is preserved, making a chewy snack rich in vitamins and antioxidants. Store in an hermetic container in a fab, dry location to maintain its texture and taste.

Papaya Leather

To make Papaya Leather, begin via manner of choosing ripe papayas. Peel the papayas, cast off the seeds, and reduce the flesh into small portions. Blend the portions proper into a smooth puree. Puree on a tightly covered tray with a thickness of around 1/8 inch. Use a meals dehydrator or low temperature oven (140°f) to dry the puree for 6-8 hours, or until it is dry and elastic, free from any adhering spots. Alternatively, you can top with a sprinkling of lime juice or powdered ginger to taste better before drying. Once dried, peel the leather from the tray and cut it into strips or shapes. Papaya leather keeps the fruit’s natural sweetness and tropical taste, imparting a chewy snack filled with nutrients and enzymes. Store in an hermetic field in a groovy, dry place to maintain its texture and taste.

Pear Leather

To make Pear Leather, begin by way of means of choosing ripe pears. Wash, peel, and center the pears, then reduce them into small portions. Blend the portions right into a easy puree. Puree on a tray and smooth it over, ensuring it is about 1/8 inch thick. To ensure the leather base is dry and non sticky, dry the puree in a meals dehydrator or oven set at 140°f for 6-8 hours. Alternating between adding a thin layer of cinnamon or nutmeg to the pinnacle before drying out for added taste. Once dried, peel the leather-based from the tray and reduce into strips or shapes. Pear leather keeps the fruit’s herbal sweetness and delicate flavor, providing a chewy snack rich in fiber and antioxidants. Store in an hermetic container in a fab, dry area to preserve its texture and taste.

Pestil (Grape Leather)

To make Pestil, also called Grape Leather, begin by deciding on ripe grapes. Wash and dispose of the grapes from their stems. Blend the grapes (which include skins and seeds) right into a smooth puree. Puree to a covered tray and smooth it until it’s roughly 1/8 inch thick. To ensure the leather is dry and non sticky, let it dry in a food dehydrator or oven at 140°f for 6-8 hours. Alternatingly, you can sprinkle a bit of powdered sugar on top to introduce sweetness. Once dried, peel the leather-based from the tray and reduce into strips or shapes. Keep it cool dry and keep it air tight. Grapes are a chewy snack rich in vitamins and antioxidants.

Pineapple Leather

To make Pineapple Leather, begin by means of selecting ripe pineapples. Peel and center the pineapples, then reduce the flesh into small quantities. Blend the pieces into a smooth puree. Spread the puree frivolously onto a covered tray, aiming for a thickness of approximately 1/8 inch. Dry the puree in a meals dehydrator or an oven set to low temperature (round 140°F) for approximately 6-8 hours, or till the leather is dry and pliable with out a sticky spots. Optionally, you could sprinkle a skinny layer of coconut flakes or lime zest on pinnacle before drying for delivered taste. Once dried, peel off the leather from the tray and reduce into strips or shapes. Chewy snack rich in vitamin c enzymes pineapple leather helps preserve the tropical flavor and natural sweetness of the fruit store in an airtight container in a dry, slick environment to preserve its texture and taste.

Strawberry Leather

To make Strawberry Leather, start by means of choosing ripe strawberries. Wash and cast off the stems from the strawberries, then mixture them right into a clean puree. Spread the puree calmly onto a coated tray, aiming for a thickness of about 1/eight inch. Dry the puree in a meals dehydrator or an oven set to low temperature (round 140°F) for approximately 6-8 hours, or till the leather is dry to the touch and pliable with out being sticky. Optionally, you could sprinkle a mild dusting of powdered sugar on top earlier than drying for introduced sweetness. Once dried, peel the leather from the tray and reduce into strips or shapes. Strawberry leather-based keeps the fruit’s natural sweetness and tangy taste, imparting a chewy snack rich in diet C and antioxidants. Store in an hermetic container in a fab, dry area to preserve its texture and taste.

Effect of Drying Conditions for Fruit Leather

Combined Convective and Far-Infrared Drying of Fruit Leather

Hot Air Drying of Fruit Leather

Hot air drying is a conventional method involving the circulation of hot air around the fruit puree. It is efficient and widely used, though it can sometimes lead to uneven drying and slight nutrient loss.

Microwave Drying of Fruit Leather

Solar Drying-Cabinet Drying of Fruit Leather

Combining solar energy with a cabinet structure, this method is energy-efficient and environmentally friendly. It provides moderate control over drying conditions, though it may be less consistent than mechanical methods.

Solar Tunnel Drying of Fruit Leather

Sun Drying of Fruit Leather

The oldest and most natural method, sun drying, relies on direct sunlight. It is inexpensive and simple but highly weather-dependent and can result in uneven drying and potential contamination.

Advantages and Disadvantages of Fruit Leather Preparation Methods

Method |

Fruit |

Advantages |

Disadvantages |

|---|---|---|---|

Gujral and Brar |

Apple | Simple method using only fruit puree | No additional ingredients to improve qualities; no preservatives for color protection |

Leiva Díaz et al |

Apple | Addition of ingredients to improve pectin-sugar-acid gelation | No preservatives for color protection |

Quintero Ruiz et al |

Apple | Addition of ingredients for color protection and quality improvement | None |

Demarchi et al |

Apple | Addition of ingredients for color protection and quality improvement | None |

Valenzuela and Aguilera |

Apple | Produces porous apple leather | No preservatives for color protection |

Bains et al |

Apple-apricot | Addition of apricot to enhance apple flavor | No additional ingredients for quality improvement; no preservatives for color protection |

Diamante et al |

Apple-blackcurrant | Addition of ingredients improves physicochemical and sensory qualities | Need to reduce drying time for better quality leather |

Sharma et al |

Apricot (wild) | Utilization of wild apricot | No preservatives for color protection |

Che Man et al |

Durian | Utilization of durian; addition of nontraditional ingredients | No preservatives for color protection |

Irwandi et al |

Durian | Utilization of durian; addition of preservatives for storage stability | Addition of nontraditional ingredients like palm oil, soy lecithin, and egg yolk |

Vijayanand et al |

Guava | Utilization of guava | None |

Babalola et al |

Guava | Utilization of guava | No preservatives for color protection |

Kumar et al |

Guava | Utilization of guava | None |

Kumar et al |

Guava-papaya | Addition of papaya to complement guava flavor | None |

Che Man and Sin |

Jackfruit | Utilization of unfertilized floral parts of jackfruit | None |

Chowdhury et al |

Jackfruit | Simple method using only fruit puree | No additional ingredients for quality improvement; no preservatives for color protection |

Okilya et al |

Jackfruit | Pretreatments on puree to improve quality | No additional ingredients for quality improvement; no preservatives for color protection |

Chen et al |

Kiwifruit | Simple method using only fruit puree | No additional ingredients for quality improvement; no preservatives for color protection |

Vatthanakul et al |

Kiwifruit | Addition of ingredients to improve qualities | No preservatives for color protection |

Jaturonglumlert and Kiatsiriroat |

Longan | Utilization of longan | No additional ingredients for quality improvement; no preservatives for color protection |

Mir and Nath |

Mango | Addition of ingredients for color protection and quality improvement | None |

Azeredo et al |

Mango | Simple method using only fruit puree | No additional ingredients for quality improvement; no preservatives for color protection |

Gujral and Khanna |

Mango | Addition of ingredients for color protection and quality improvement | None |

Gujral and Brar |

Mango | Addition of ingredients for color protection and quality improvement | None |

Pushpa et al |

Mango | Nutritionally enriched mango leather | Addition of nontraditional ingredients like corn flour, soy flour, and skim milk powder |

Chan and Cavaletto |

Papaya | Addition of ingredients for color protection and quality improvement | None |

Babalola et al |

Papaya | Addition of ingredients to improve qualities and storage stability | No preservatives for color protection |

Huang and Hsieh |

Pear | Addition of ingredients to improve qualities | No preservatives for color protection |

Maskan et al |

Pestil (grape) | Utilization of grape juice | No preservatives for color protection |

Phimpharian et al |

Pineapple | Addition of ingredients to improve qualities | No preservatives for color protection |

Lee and Hsieh |

Strawberry | Addition of ingredients to improve qualities | No preservatives for color protection |

Effect of Fruit Leather Packaging and Storage

Packaging Materials of Fruit Leather

Selecting the right packaging material is vital. Common options include:

- Plastic Wraps: A barrier in opposition to moisture and oxygen, however may not be environmentally friendly.

- Vacuum Sealing: It reduces the amount of oxygen inside the air, ensuing in an extended period of color and taste.

- Aluminum Foil: it’s good defense against light and air, but clunky.

- Biodegradable Films: A sustainable solution that balances protection and sustainability.

Storage Conditions of Fruit Leather

Storage conditions play a pivotal role in preserving fruit leather quality. Key factors include:

- Temperature: Cold temperatures slow down degradation, so refrigeration is best for long-term storage.

- Humidity: Moisture content keeps the texture moist and prevents mold growth.

- Light: Keeping fruit leathers in dark environments protects them from photodegradation.

Shelf Life of Fruit Leather

Conclusions

The preparation of fruit leathers involves diverse methods and conditions that significantly influence their final qualities. From apple to pineapple, every fruit’s particular characteristics have interaction otherwise with numerous drying techniques which include convective, infrared, microwave, and sun drying. Understanding these effects is vital for optimizing the feel, taste, and shelf existence of fruit leathers. Furthermore, the choice of packaging and storage conditions further impacts their stability and consumer acceptability. This article explores these aspects comprehensively, offering insights that are essential for both researchers and food industry professionals aiming to enhance fruit leather production.

FAQs About Fruit Leather

Q: How would you describe fruit leather?

A: Fruit leather is a dried, flexible sheet crafted from pureed culmination which might be spread thinly and dried till they come to be leathery in texture.

Q: What is the use of fruit leather?

A: Natural product leather fills in as a close by and compact tidbit, introducing a home grown supply of nutrients, fiber, and strength. It likewise can utilized in prepare, as a garnish, or as a component in various recipes.

Q: What is the principle of fruit leather?

A: The precept of fruit leather involves getting rid of water from pureed fruit thru drying, which concentrates the flavors and preserves the fruit whilst retaining its natural sugars and nutrients.

Q: What is the fruit leather method?

A: The natural product leather strategy regularly includes blending shimmering climax solidly into a puree, spreading the puree onto a level floor or plate, after which drying it utilizing different procedures alongside broiler drying, sun drying, or dehydrator drying. The decision of surrender outcome, parts (if any), and drying conditions can influence the surface, flavor, and rack ways of life of the end result.